QualCert Level 2 Certificate: Enhancing QA Skills with Self-Check Sheets

Table of Contents

Task Overview:

Objective:

This task establishes the fundamental knowledge required for the entire qualification. You will learn the critical difference between “checking” work and “assuring” work. You will also analyze the financial impact of poor quality on a UK business using the “Iceberg Model.”

Learning Outcomes Covered:

- LO1: Understand the difference between Quality Assurance (QA) and Quality Control (QC).

- LO3: Understand the commercial impact of quality failures (Cost of Poor Quality).

Part 1: Theory – QA vs. QC:

Many people use the terms Quality Assurance and Quality Control interchangeably, but in a professional UK industry setting, they are very different.

1. Quality Control (QC) = Detection (The “Police”)

- Definition: QC is product-oriented. It focuses on defect identification.

- Action: It happens after the work is done.

- Example: An inspector measuring a part at the end of an assembly line, or a proofreader checking a document before printing.

- Drawback: It is reactive. If you find a fault, the time and material have already been wasted.

2. Quality Assurance (QA) = Prevention (The “Process”)

- Definition: QA is process-oriented. It focuses on defect prevention.

- Action: It happens before and during the work.

- Example: Creating a Standard Operating Procedure (SOP), training staff, or calibrating machinery so it doesn’t produce errors.

- Benefit: It ensures “Right First Time,” saving money and time.

The Medical Analogy:

- QA is eating healthy and exercising to prevent illness.

- QC is taking medicine to fix the illness after you get sick.

Part 2: Theory – The Cost of Poor Quality (The Iceberg):

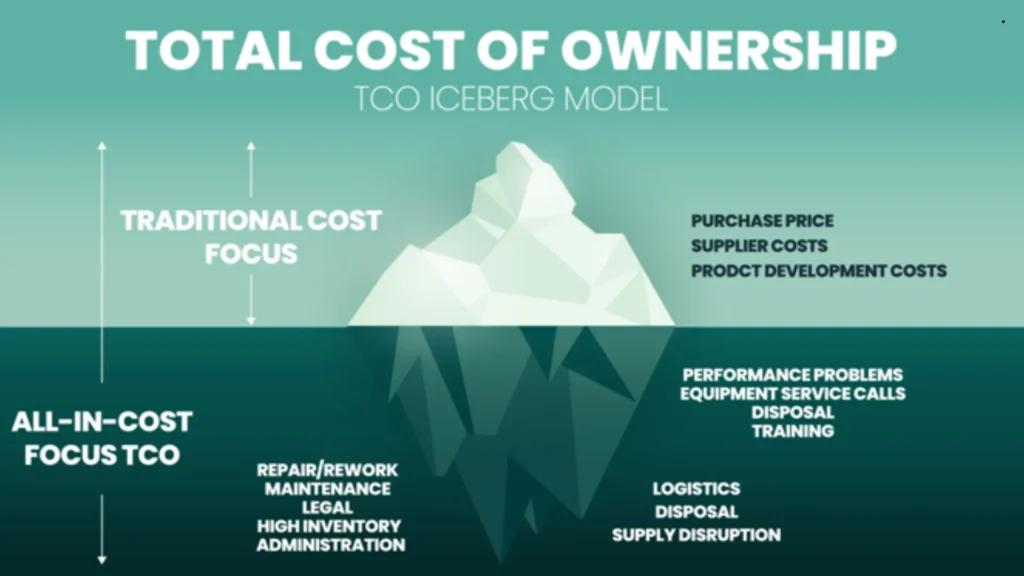

When a quality failure occurs in a business, managers often only see the immediate costs. However, meaningful Quality Assurance understands that the hidden costs are often much higher. This is known as the “Iceberg Model” of Quality Costs.

1. Visible Costs (The Tip of the Iceberg):

These are easy to see and calculate in British Pounds (£).

- Scrap (Throwing away bad materials).

- Rework (Paying staff to fix the mistake).

- Warranty claims (Replacing the item for the customer).

2. Hidden Costs (Below the Water):

These are dangerous because they are harder to track but damage the business more.

- Loss of Reputation: Unhappy customers tell their friends (or post on social media).

- Late Deliveries: Penalties for missing deadlines.

- Management Time: Time spent investigating errors instead of planning growth.

- Low Morale: Staff feel frustrated fixing the same errors repeatedly.

Part 3: Learner Activity – The Categorization Task

Instructions: Look at the list of workplace activities below. Tick whether the activity is QA (Prevention), QC (Detection), or a Cost of Failure.

| Workplace Activity | QA (Prevention) | QC (Detection) | Cost of Failure |

| 1. Writing a new Training Manual for staff. | |||

| 2. Testing a sample of paint in a lab after mixing. | |||

| 3. Throwing away 50kg of burnt ingredients. | |||

| 4. Calibrating a thermometer to ensure accuracy. | |||

| 5. An external auditor checking the company accounts. | |||

| 6. Paying overtime to re-make a late order. |

Part 4: Vocational Case Study – “Brumby Engineering Ltd”

Instructions:

Read the scenario below and answer the analysis questions.

The Scenario:

Brumby Engineering, a small manufacturer in Birmingham, produces metal brackets for the construction industry.

To save money, the Production Manager decided to cancel the monthly maintenance check (QA) on the cutting machine, saving the company £200 in technician fees.

Two weeks later, the unmaintained machine slipped out of alignment. It produced 5,000 brackets that were 2mm too short. This wasn’t noticed until the final inspection (QC).

All 5,000 brackets had to be scrapped (Metal cost: £1,500). The team had to work the weekend (Overtime pay: £800) to remake them so they wouldn’t miss the delivery deadline.

Analysis Questions:

Q1. The False Economy:

The Manager tried to save £200 by skipping QA. What was the total visible financial loss caused by this decision?

(Show your working).

Q2. The Hidden Cost:

Even if they managed to remake the parts over the weekend, what “Hidden Cost” might impact the staff due to this incident?

Q3. The ISO 9001 Principle:

Which ISO 9001 principle did the manager fail to follow? (Select one).

- A) Evidence-based decision making.

- B) Relationship management.

- C) Customer focus.

Q4. Reflection:

In your own words (approx. 50 words), explain why investing in the maintenance check (QA) would have been “Cheaper” than relying on the final inspection (QC).

Submission Guidance

- Format: Save this document as a PDF titled [Your Name]-Unit01-KPT01.

- Upload: Submit to the LMS for your assessor to review.

- Grading: This task contributes to AC 1.1 and AC 3.1.