QualCert Level 2: Process Control Workshop

Unit 2: Process Control Basics

Table of Contents

Workshop Objective

To bridge the gap between “understanding” a process and “demonstrating competency” in a vocational setting. You will learn to identify how specific workplace actions fulfill the evidence requirements for your Level 2 qualification.

1. Defining Process Control in the UK QA Landscape

Learning Outcome: Define the concept of process control and its relevance in QA.

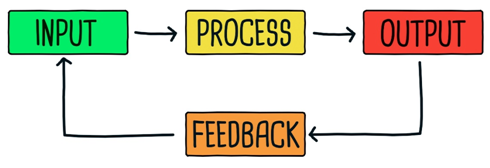

In a vocational context, process control is not just a definition; it is the active management of variables to ensure every output is identical.

- The Competency: Being able to explain why we stop a line when a variable shifts.

- UK Regulatory Link: This aligns with the Health and Safety at Work etc. Act 1974, where maintaining controlled processes is vital for operator safety, and the Consumer Rights Act 2015, ensuring goods are “of satisfactory quality.”

- Evidence Requirement: A written or verbal statement describing a specific process in your workplace and identifying the “Control Points” where quality is checked.

2. Techniques and Applications (The “How-To”)

Learning Outcome: Identify different types of process control techniques and their applications.

We move from theory to the tools you use daily. At Level 2, you are expected to identify and use these tools, not just name them.

| Technique | Vocational Application | Evidence Type |

| Statistical Process Control (SPC) | Using Control Charts to plot weights, temperatures, or dimensions. | Uploading a completed Control Chart from a shift. |

| Standard Operating Procedures (SOPs) | Following a step-by-step guide to calibrate machinery. | An Assessor Observation of you following an SOP precisely. |

| Poka-Yoke (Mistake Proofing) | Using jigs or software locks that prevent the next step if the current one is wrong. | A photo or video of a physical constraint used in your workflow. |

3. Product Consistency & Consumer Protection

Learning Outcome: Understand the relationship between process control and product consistency.

Consistency is the heartbeat of Quality Assurance. In the UK, failing to provide consistent products can lead to breaches of Trading Standards.

- The Vocational “Why”: If a food manufacturer produces a batch of “Low Salt” soup but the process isn’t controlled, some cans may contain dangerously high sodium.

- Competency Aspect: You must demonstrate how you identify a “Non-Conformance.”

- Evidence Requirement: A witness testimony from a supervisor confirming you identified a product that fell outside of the “Tolerance Band” and took corrective action.

4. Monitoring and Controlling to UK Standards

Learning Outcome: Learn how to monitor and control processes to meet established quality standards.

This is the “Action” phase of your assignment. It involves real-time monitoring and the authority to intervene.

Key Knowledge Pillars:

- Input Monitoring: Checking raw materials (e.g., checking a delivery note against UK food grade standards).

- Process Monitoring: Checking the “In-Process” variables (e.g., checking the temperature of a chemical bath every 30 minutes).

- Output Monitoring: Final inspection before the product leaves the bay.

Vocational Task for your Portfolio:

The “Audit Trail” Exercise: Select one batch of work. Trace it from the moment it entered your station to the moment it left. Provide the logs, sign-off sheets, and any digital timestamps that prove the process stayed within the “Control Limits.”

Summary of Evidence Required for AC Linkage

To successfully complete this unit, your portfolio should contain:

- Product Evidence: Annotated copies of your daily check sheets or SPC charts.

- Professional Discussion: A recorded 5-minute chat with your assessor explaining how the Provision and Use of Work Equipment Regulations (PUWER) 1998 relates to your specific machinery’s quality output.

- Observation Record: Your assessor watching you perform a “Start-of-Shift” calibration or quality check.